Keeping Things Fresh: Innovation through Experimentation.

In product development, progress isn’t just about keeping up with demand, it’s about utilising opportunities to explore what’s possible. At DisplayMode, we know that some of our most exciting ideas have emerged not during the busiest production runs, but in those moments when we’ve had a little spare capacity to try something new. Our in-house design and experienced production teams love having the time to get their creative heads together, thinking differently about how we tackle challenges, and coming up with solutions to problems that don’t even exist yet.

Making time for innovation

When our injection moulding machines are running flat out, our priority is meeting customer needs and keeping stock levels high to allow for rapid turnaround times on orders. But when production eases, we gain the freedom to experiment a little. Testing new materials, refining processes, and asking “what if?”. It’s during these quieter stretches that new ideas get the chance to move out of the minds of our team, and onto the shop floor.

Playing with colour: beyond the standard frame

One of the areas we’ve been exploring is the use of coloured plastic pellets in our injection moulding process. Traditionally, our sign holders have focused on clarity and durability… but what happens when you introduce colour into the mix?

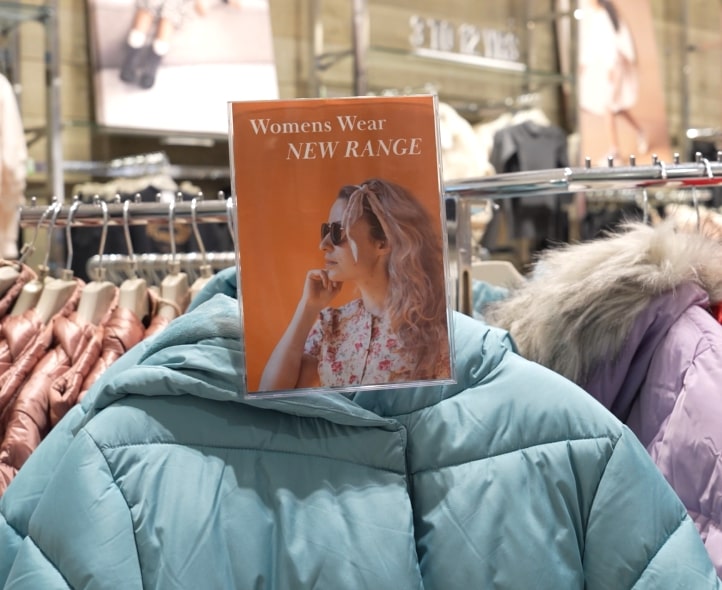

By experimenting with tinted pellets, we’ve discovered exciting opportunities for edge-glow sign holders. When combined with natural lighting, these coloured frames don’t just hold a sign, they enhance it by creating a glowing colourful border that draws the eye and adds visual impact.

Testing materials, building knowledge

These experiments aren’t just about aesthetics for us. Sometimes we hit the nail on the head first time, sometimes the ideas don’t work out as we’d hoped, and sometimes they need further investigation. Testing different pellet formulations allows us to understand how the colour intensifies, how the sign holder durability changes, and how to improve production efficiency. Each trial helps us answer important questions:

Even when an experiment doesn’t lead directly to a new product, it adds to our knowledge base, making us faster to react and more confident in our approach when the next opportunity arises.

Turning curiosity into customer value

For us, innovation isn’t just about technology; it’s about helping our customers present their messages more effectively. Whether it’s a glowing frame that catches attention in a busy store, or a subtle tint that complements a brand’s identity, providing that sense of belonging.. these small experiments have the potential to become big wins in real-world use.

By making space for curiosity, and by treating spare capacity as a chance to learn, we ensure that Reflex Sign Holders continue to evolve; not just keeping pace with the market but growing, diversifying and improving.